Inventory and spare parts management

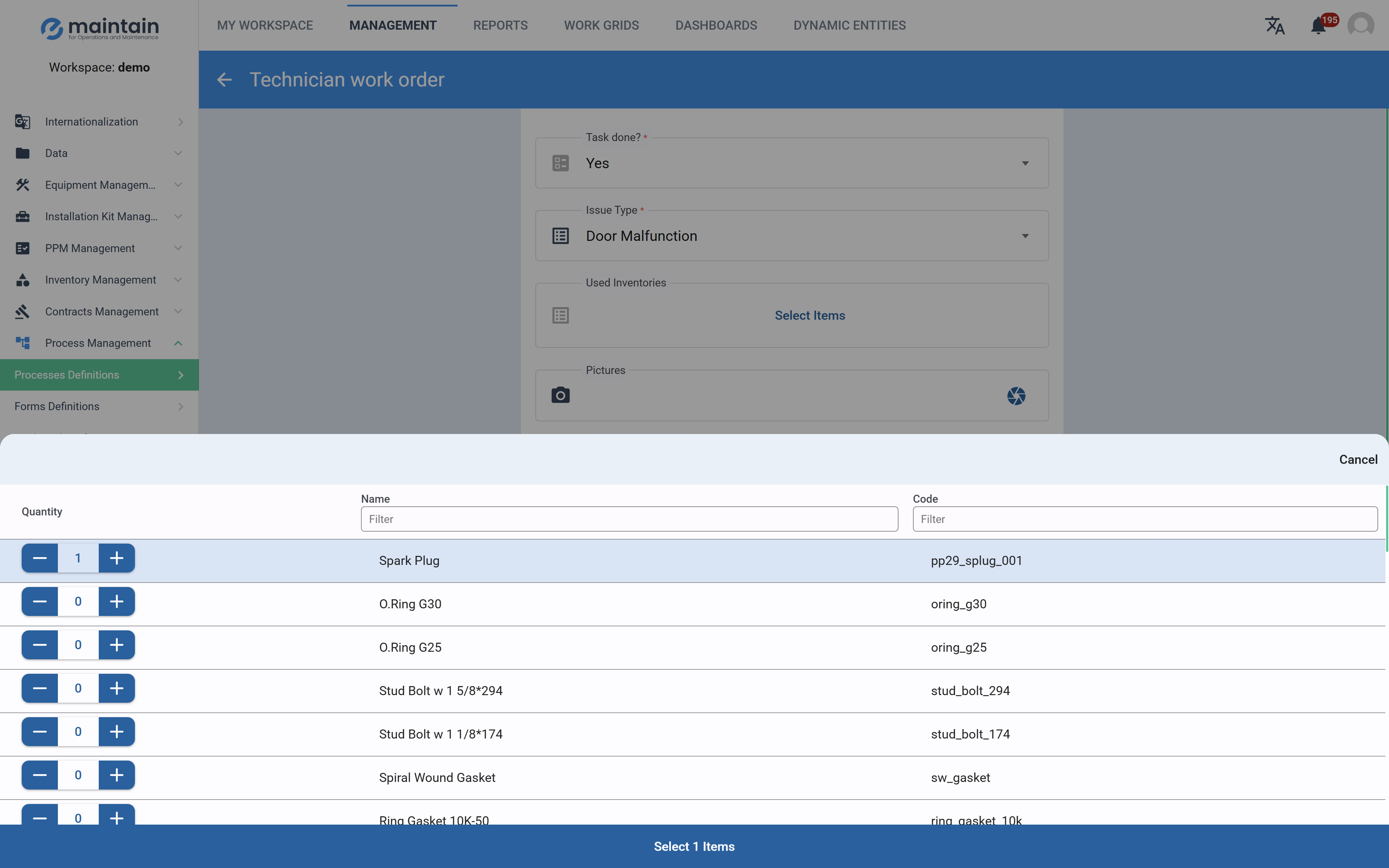

The Inventory Module within our e-Maintain is designed to serve as the centralized repository for managing stock and spare parts efficiently. It offers a robust set of features to ensure accurate tracking, seamless integration with other modules, and streamlined inventory management processes.